Introduction:

Research for the OMT pages began in the Autumn of 2015, and they were last updated in December 2024. If you are aware of any errors, or would like to add further details or personal memories, please email david@newall.org.uk.

Ray Morris kindly supplied many of the factory photos used here.

We acknowledge the help and encouragement given by the management of Rotary Precision Instruments UK Ltd with special thanks to Ian Whitehead, Technical Director, for his generous personal assistance, particularly with some of the later OMT history and for providing access to a number of relevant artefacts.

Thanks also to Stan Gibbs, who (along with his twin brother Dave) joined OMT in Maidenhead in 1952 as an apprentice straight from school and stayed with the firm (and its subsequent owners) until he retired in 2002. Many of the documents reproduced here are from his personal collection. In August 2016 the author had the pleasure of visiting Stan at his home and was able to photograph his beautiful boxed collections of optical components, as well as humbly accepting a set that Stan had put together as a gift. They are all shown on these pages.

We are indebted to Georgina Madge, a volunteer researcher at the Maidenhead Heritage Centre, for her help concerning the early history of the OMT building in Maidenhead.

Details of some of the early OMT products have been taken from the excellent OMT Handbook (1st edition, published in 1943). Descriptions of some later products are recounted from personal memory and experience, as well as from the company’s published literature.

Important Note. Please be aware that we are unable to provide Service Manuals, Operating Instructions, Assembly Drawings or Electrical/Hydraulic/Pneumatic Schematics for any of the machines and instruments manufactured by the Newall Group; we simply do not have access to them. We are unable to help with the repair, refurbishment or operation of any of the products. All the data that we hold is available for free download from the “References” pages that can be found within the relevant sections on the Companies/Divisions tab.

Early History:

It appears that the company was formed in 1939/1940 by Newall Engineering to manufacture metrology equipment, optical components and precision inspection products to support its machine tool business. It started production in Slough where they apparently took over a small local optical company and soon opened a second factory, in Maidenhead. A newspaper article (Reading Mercury, August 3rd 1968) suggests this small local optical company was located in Maidenhead but we believe this is inaccurate. Certainly, they were operating from Slough before acquiring premises in Maidenhead.

We are grateful to Nick Forder, the curator of the Maidenhead Heritage Centre, who contacted us in November 2024 to say that he had unearthed a 1956 school project on “Industries in Maidenhead”. Here is a transcript of an exchange that took place between two schoolgirls and an OMT spokesman:

- Why is your factory located in Maidenhead? Largely by accident. We took over premises owned by one of our larger subcontractors and enlarged those premises when it became necessary to leave Slough Trading Estate.

- What products do you make ? Precision measuring instruments for the engineering industry.

- What raw materials do you use in the making of your products ? Steel and iron and aluminium castings.

- What are the sources of your raw materials ? Mostly Sheffield and the Midlands, with a small proportion of aluminium castings from local foundries.

- What form of transport do you use ? In this country – own lorry. Abroad – instruments suitably packed to prevent them from damage.

- How many employees do you have ? Approximately 230.

- What is the proportion of male and female workers ? Apart from clerical staff, we employ only 6 or 8 girls in the factory.

- From where do you draw your labour resources ? Anywhere within a range of fifteen miles.

- What hours do you work ? A normal engineering week is 44 hours plus a certain amount of overtime.

Factories & Operations:

Slough – 414 Montrose Avenue, Slough Trading Estate, Slough, Buckinghamshire (in those days). (Telephone Slough 20247/8; Telegrams “Optool” Slough). Records show it was still trading from this address as a subsidiary of Newall Engineering at least until February 1953. We understand optics continued to be manufactured in Slough until a factory fire prompted the transfer of those operations to the Maidenhead factory in late 1952, and the Slough facility closed soon afterwards. Unfortunately, we have not been able to unearth any images of the Slough factory. Much of the Slough Trading Estate has been redeveloped and modernised since those days. Number 414 Montrose Avenue is now a modern small industrial unit occupied by a BMW Service Centre (July 2016).

But in March 2017 we were excited when Ron Goodman emailed us from Australia. Here is what he wrote:

“After a concentrated course as an Instrument Maker at a Government Training Centre, I worked at OMT, Montrose Avenue, Slough. As a young man, I was there from 1940 to 1950, when I then came to Australia. I built their very first Toolmaker’s Microscope, and when I resigned I was assistant to the Chief Inspector.

In 1940 the OMT factory at Slough comprised two oldish long and narrow single storey buildings, opposite each other on Montrose Avenue. The main one housed managers’ & general offices, machine shop, store, vertical omtimeter & tank telescope gun sight assembly, and Inspection. Scattered around the outside were the separate small buildings of drawing office, paint shop and heat treatment. The optical workshop was located in part of the other building.

The machinery and fittings were old, and appeared to have been there a long time. However, all the optical components needed at that time were made there, except for the graduated mirrored ring fitted in the rotary tables. These I believe were bought in from Hilger-Watts, London. The rest of this building was occupied by a carrier business which soon left, and this space then became the rotary table workshop.

I think that it was early in 1941 when a new 2-storey building was added to the main building, the ground floor being a temperature-controlled dust-free area, housing instrument assembly and the Test House. The upper level, accessed by an outside staircase, included a new Manager’s Office, Drawing Office, Optical Design, and General Office. The old Drawing Office then became the canteen”.

The Mars confectionery factory was on the same Trading Estate in Slough. One of our contributors, whose father worked in the Slough factory in the 1940’s, and who was a young child at the time remembers him bringing home a Mars bar at the end of each week. This was quite a treat because sweets were still on ration following the war, and Ron has the following to say on the subject:

“Mars bars: good fun! The girls there worked shorter hours than we did, and at 5:30 pm a group of them would walk home via Montrose Avenue. It was no problem for the younger lads to find a legitimate reason to cross the road at this time. The story was that the girls were allowed a small ration, but they just could not eat them anymore. I suppose that sounds reasonable. Therefore, there always seemed to be some Mars bars somewhere around in OMT.”

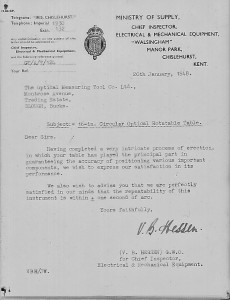

The following letter shows the company was held in high regard by the Ministry of Supply. (See the feature “Just a Second” on our OMT Products Page 2 for an appreciation of just how accurate one second of arc really is).

Maidenhead – Oldfield House, 142 Bridge Road, Maidenhead, Berkshire. (Telephone Maidenhead 26171). The factory occupied a site on the corner of Bridge Road and Oldfield Road.  Again, we are disappointed not to have found any images of the exterior of this factory. Please get in touch if you know of any. But Stan Gibbs (good old Stan!) has sent us a photo of part of the machine shop.

Again, we are disappointed not to have found any images of the exterior of this factory. Please get in touch if you know of any. But Stan Gibbs (good old Stan!) has sent us a photo of part of the machine shop.

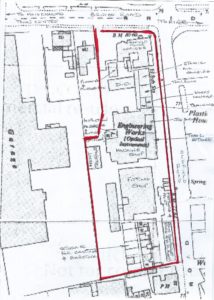

In October 2020 former employee Brian Groves found a copy of an old OS map with the outline of the factory site marked on it. With some help from his old colleague, Bob Peacock, he used this as a starting point to create the following sketch (from memory) of the functions of the various buildings around the site. We are indebted to both of them for taking the time to produce this for us. (Click on the image to enlarge):

Following the closure of the Maidenhead factory, it is believed the site was acquired by an oscilloscope manufacturer (Tektronix?) but it has now become a large block of modern flats.

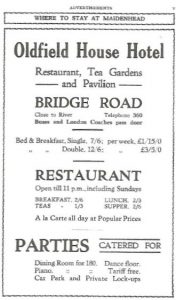

An OMT drawing has been found that indicates the building was formerly the Oldfield House Hotel, and shows the proposed changes to turn it into a showroom and offices. We thank Georgina Madge, a volunteer researcher at the Maidenhead Heritage Centre, for her diligence on our behalf which has led to the discovery of the following four documents and photos from the collection of Brian Boulter, a former curator of Maidenhead Heritage Centre. (Click on the images for a clearer view).

The first item is an advertisement for the Oldfield House Hotel (taken from the 1927/1931 guide book), showing that it must have been an impressive establishment, catering for up to 180 diners and offering an A la Carte menu all day, including Sundays, up to 11 p.m. A double room with breakfast included could be had in those days for the princely sum of 12/6d (12 shillings and sixpence – about 62.5p in today’s money).

The second item is a photograph of Bridge Road (flooded, as it often was). Oldfield House is the large double-fronted building in the distance, just beyond the group of cars following the cyclists.

Finally, we have extracts from local trade directories, dated 1963 and 1966, showing the relevant entries for OMT.

In October 2019 we were contacted by Phil Richards, who came across our website while doing his own research on Maidenhead. He had been looking at Bridge Street and found the following photos which he has kindly shared with us. They show the Oldfield House building as it looked in 1918 and in 1929. (Click the images to enlarge)

Phil also included the following aerial photo of Maidenhead in 1947, with the corner of Bridge Street and Oldfield Road identified by the red rectangle. The small yellow rectangle marks the Oldfield House Hotel building (OMT office/showroom), and the larger yellow rectangle identifies the factory buildings. Flooding seems to have been a frequent occurrence in those days. You can find a description of the impact the 1947 floods had on operations at OMT, on pages 27 and 33 of the Newall PRECISION group magazine dated November 1947, which can be found on our Photo Gallery page.

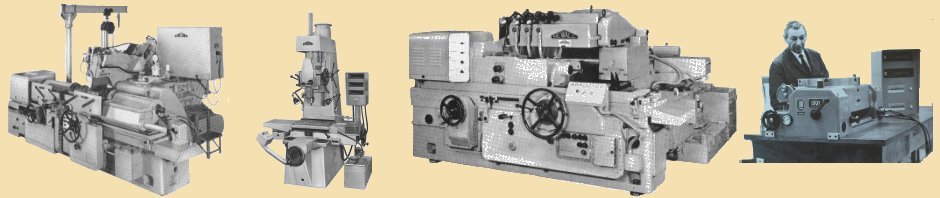

The company was initially required to produce high quality rotary tables as an accessory for the range of Newall jig boring machines, which were in high demand during the war years as Britain geared up for all-out production of aircraft and weaponry. Inspection departments around the country needed inspection equipment such as Toolmaker’s Microscopes, which in the pre-war era had been imported from the well-respected German Zeiss organisation. OMT started manufacture of their own version of this equipment, which became one of its best-known products. During the war, the company also built tank periscopes and telescopes.

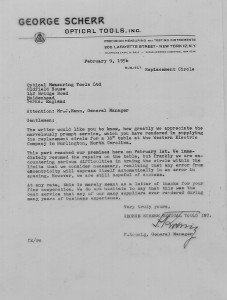

A letter from George Scherr Optical Tools Inc. (who became OMT agents in the USA) shows the company was providing outstanding after-sales service from Oldfield House:

Following several years of close collaboration with the National Physical laboratory (NPL), in 1946 the company received permission to certify its own products to NPL standards, a rare privilege also shared by the parent company Newall Engineering, which established an independent NPL-approved standards room at its Peterborough site.

As the war came to an end and the demand for some of its products diminished, it became clear that new product lines would be required if it was to keep all of its 100 employees in work. One lucky break came when the Rank Organisation approached the Newall group to make a cine film camera. Together with Newall Engineering, they went on to produce about 200 cameras costing up to £8000 each. Full details can be found on our Newall Engineering Products Page 1.

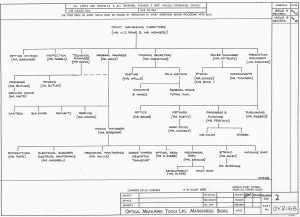

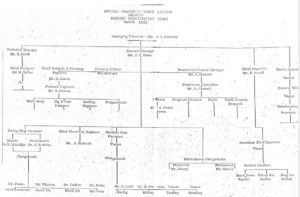

We have discovered this diagram outlining the management structure at OMT in 1966.

A newspaper advertisement from the 1960’s (OMT Vacancies) indicated a typical rate of pay for skilled machinists of 10/1½ (10 shillings and three-halfpence – approximately 50.5p) per hour. A catalogue of products manufactured in Maidenhead can be downloaded here (size 6MB).

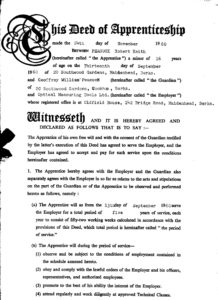

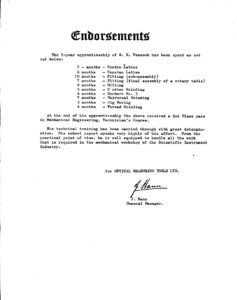

Bob Peacock signed up for a 5-year apprenticeship with OMT when he left school in 1960. Here is the first page of his Deed of Apprenticeship, together with the Endorsements achieved after the five years. They are signed by Jack Hann, General Manager.

High Wycombe – Wellington Road, Cressex Industrial Estate, High Wycombe, Buckinghamshire. As the company grew, space became a problem in Maidenhead so a second factory was established in High Wycombe and production of optical components including diffraction gratings was transferred here in the early 1960’s.

High Wycombe – Wellington Road, Cressex Industrial Estate, High Wycombe, Buckinghamshire. As the company grew, space became a problem in Maidenhead so a second factory was established in High Wycombe and production of optical components including diffraction gratings was transferred here in the early 1960’s.

Mark Valentine was an apprentice in the coating department from 1976 to 1978 at a time when the factory was in significant decline. You can see his comments on our feedback page. Mark has been able to identify the gentleman in the photo of the coating department as the “lovely man”, Jack Freeland. He tells us that Ron Gardener was MD in those days, sharing his time between High Wycombe and Fakenham. Mark says that Ken Brown was in charge of the Grating Department, with help from Morris, Eric and David and lovely old Mickey Lord. Other personnel included Bob Baker (workshop foreman), “Dabber”, Jerry, Peter (polishing department), Reg “the edge” and his son Chris (edging in the roughing shop) and Monty Angold, who was self-employed.

A catalogue of items manufactured in High Wycombe can be downloaded here (size 2MB).

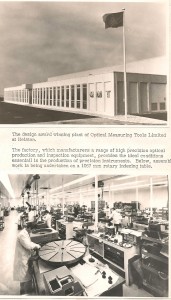

Helston – Water-ma-Trout, Helston, Cornwall, TR13 0LW. (Telephone Helston 3311; Telegrams OPTOOL Helston.) OMT were persuaded to start operating from a brand new purpose-designed factory in Helston under a government-inspired scheme to bring industry to Cornwall.  The precise date is unclear but we have discovered manufacturing drawing masters dated August 1969, some with the Maidenhead address and others with Helston, so presumably by this time the new factory was either in use or well on the way to being so.

The precise date is unclear but we have discovered manufacturing drawing masters dated August 1969, some with the Maidenhead address and others with Helston, so presumably by this time the new factory was either in use or well on the way to being so.  [[ We now know the factory opened in 1969. ]] The entire factory was air-conditioned and dust-controlled to a high standard and it provided a very pleasant working environment. All OMT production transferred to Helston and this resulted in the closure of the Maidenhead and High Wycombe plants, as announced in this Maidenhead Advertiser press cutting supplied to us by Brian Groves. Brian also provided the following Organisation Chart from March 1969 (click to enlarge), so this confirms that the factory was in operation by then.

[[ We now know the factory opened in 1969. ]] The entire factory was air-conditioned and dust-controlled to a high standard and it provided a very pleasant working environment. All OMT production transferred to Helston and this resulted in the closure of the Maidenhead and High Wycombe plants, as announced in this Maidenhead Advertiser press cutting supplied to us by Brian Groves. Brian also provided the following Organisation Chart from March 1969 (click to enlarge), so this confirms that the factory was in operation by then.

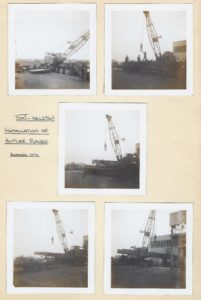

Brian Groves also told us how a large Butler planing machine was installed in the factory in 1973. The crane used to offload the machine from its transport looks a bit primitive by today’s standards as you can see from this photo collage.

Brian Groves also told us how a large Butler planing machine was installed in the factory in 1973. The crane used to offload the machine from its transport looks a bit primitive by today’s standards as you can see from this photo collage.

Brian also provided copies of two interesting OMT-related articles, both from Industry Week, January 1970, and are available for download. The first article is exclusively about the OMT factory. The second article compares aspects of the OMT building with other leading-edge factories of the day. Ironically, one of the other companies featured is Horstmann Gear, in Bath, who feature in the late history of OMT (see below).

It had been intended to transfer some jig borer production from Peterborough to Helston and a number of key personnel were persuaded to make the move to rural Cornwall. Initially, some parts were machined in Peterborough and shipped to Helston for final assembly but  full production did eventually start in Helston. The first such machine, a “2030”, was successfully completed and we understand the paint finish was to the usual incredibly high OMT instrument standard, rather than the Newall machine tool standard, making it a one-off. Unfortunately, it was to remain a one-off because that was the first and last such machine to be manufactured there before the plant was closed. Some members of staff had no sooner arrived in Cornwall and bought new houses, than they had to sell up and move straight back to Peterborough.

full production did eventually start in Helston. The first such machine, a “2030”, was successfully completed and we understand the paint finish was to the usual incredibly high OMT instrument standard, rather than the Newall machine tool standard, making it a one-off. Unfortunately, it was to remain a one-off because that was the first and last such machine to be manufactured there before the plant was closed. Some members of staff had no sooner arrived in Cornwall and bought new houses, than they had to sell up and move straight back to Peterborough.

The collapse of Rolls-Royce in 1971 had severely affected the entire Newall group, who had many Rolls-Royce orders on their books at the time and the Helston venture ultimately failed. Their fortunes were not helped because of the scarcity of skilled personnel, or people who were willing to learn those skills, in that remote location. The very remoteness of the plant resulted in increased operating costs and this was a further burden the company had to bear. When the closure of the factory finally took place (1974), that beautiful building suffered the indignity (in the opinion of the author!) of being used for the production of Levi jeans.

John Hughes contacted us (see our Feedback page) in February 2019 and advised us that the Helston factory building is now split into a number of smaller units, with the front part being occupied by Helston Gunsmiths. In February 2022 the author visited the site and took some photos of the front of the building and the car park (and contents!). Most of the building is occupied by Helston Gunsmiths, with a small part being used as a health/fitness centre. When thinking of a typical gunsmiths retail outlet, I certainly did not expect to find examples of quite such a large calibre as those currently occupying the front car park! Here are a few images to show you what we mean. (Click the images to enlarge).

Awards:

On 21st April 1968 the company received The Queens Award for Enterprise: Export & Technology (Combined) for “Export achievement and for technological innovation in the production of high precision optical scales by a photographic process.”

Late History:

Back in 1973 when Newall announced its intention to close the OMT Helston factory, questions were raised in the House of Commons about the likely impact this would have on the country’s exports and imports, as well as the effect on the engineering and allied trades. The Secretary of State for Trade and Industry, Mr. Anthony Grant, replied “I have been informed by the parent company that there is no intention to cease manufacture of this equipment. Manufacture is to be transferred to other premises of the Newall Group.” (source: Hansard HC Deb 26 November 1973 vol 865 cc14-5W).

However, it seems Newall later had a change of heart because an OMT letter dated 1st October 1974 and sent out to OMT customers, indicated that two of the most popular product ranges (Rotary Tables and Toolmaker’s Microscopes) would in future be manufactured by Windley Brothers Ltd (manufacturers of the world-famous Crown-Windley surface plates). A few OMT key employees were offered jobs at Windley Brothers’ Chelmsford factory to help establish production of these devices, although in the end none of them accepted. (Perhaps Essex didn’t hold the same charms as Cornwall…). It is unclear whether Windley did actually produce any OMT instruments but after a short while the two ranges in question were back under Newall control and, together with the other remnants of OMT, were transferred to the Newall Tooling division in Fakenham, Norfolk. Here is a nameplate from a rotary table that was offered for sale in 2022: Further details of the Fakenham factory can be found here.

Further details of the Fakenham factory can be found here.

[[ In September 2020 Brian Groves (who worked at OMT for 10 years and studied for an MBA in Manufacturing Operations Management and Industrial Marketing at Cranfield) told us that during the latter part of his time at Cranfield, with a few of his fellow students he carried out a project which involved negotiating with Newall Engineering regarding a possible purchase of the rights to manufacture OMT products , which had just been put up for sale. Brian had told Newall that he regarded the proposed royalty they required as being totally unrealistic. In a letter to Brian, Bill Rea (the Newall MD), expressed his opinion that “I am quite satisfied that the OMT product line placed in another operating company as supplementary products can be sold at prices and with costs such that an adequate profit can be earned and a royalty of the rate I have proposed paid. The only real question about royalty is for how long it should continue to be paid.” Brian thinks perhaps the experience of Windley Brothers somewhat exonerates his assertion! ]]

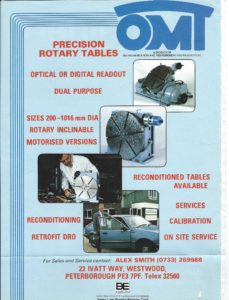

Discovery of this B. Elliott/OMT brochure  shows that rotary tables were marketed at some point from Ivatt Way in Peterborough, which was also the Newall Electronics address. The brochure features a Newall Electronics Digipac 5 readout system, which suggests this was after the business closed down in Helston, as all OMT sales literature from that era shows nothing later than Digipac 4. It seems likely that this was after the dalliance with Windley Brothers and before finally moving to Fakenham, but we have no proof of this at present.

shows that rotary tables were marketed at some point from Ivatt Way in Peterborough, which was also the Newall Electronics address. The brochure features a Newall Electronics Digipac 5 readout system, which suggests this was after the business closed down in Helston, as all OMT sales literature from that era shows nothing later than Digipac 4. It seems likely that this was after the dalliance with Windley Brothers and before finally moving to Fakenham, but we have no proof of this at present.

Brian Groves supplied us with another sales leaflet, (see below, right) providing further proof of OMT operations being carried out from the Newall Electronics base in Ivatt Way.

Following the closure of the Helston plant, several OMT employees (Ray Butler, Dave Gibbs, Stan Gibbs) moved to join Horstmann Gauge & Metrology in Bath, to develop a range of precision rotary tables.

In 1986 Horstmann sold the rotary table product to Airmatic Engineering (UK) Ltd which had a factory in Sileby, Leicestershire, who were also manufacturing rotary tables and air bearing slides. The ‘Horstmann Division’ was re-located at the Maltings Industrial Estate in Bath with Ray Butler as managing director. The remains of the OMT business were acquired several years later and transferred to Bath from the Newall site at Fakenham.

The holding group of Airmatic Engineering subsequently purchased Machinenfabrik Eimeldingen, the manufacturer of large machining rotary tables, located in the village of Eimeldingen in south west Germany. Airmatic Engineering (UK) Ltd acted as its agent in the UK and in 1998 changed its name to Eimeldingen UK.

In 2004 the German site was sold and the Bath business changed its name to Rotary Precision Instruments UK Ltd. In November 2011 the business was acquired by HUBER Diffraktionstechnik GmbH & Co. KG but (in 2016) continues to trade under the RPI name.

Records held by Companies House show that Optical Measuring Tools Ltd and also O.M.T. (Optics) Ltd were both struck off the Register of Companies on 19th April 2005 and dissolved by notice in the London Gazette dated 26th April 2005. Both applications were made by B. Elliott Ltd.

Postscript:

Soon after starting to research the OMT story, the author was visiting Bath and made an unannounced visit to Rotary Precision Instruments UK Ltd. The timing of the visit couldn’t have been more fortuitous because just a matter of days before, they had decided to dispose of all the old OMT records and had intended to make a large bonfire of them. But it rained so heavily that they waited for the weather to dry up a little, so they were mostly still there when I came knocking at their door, and I was given permission to take whatever I wanted.

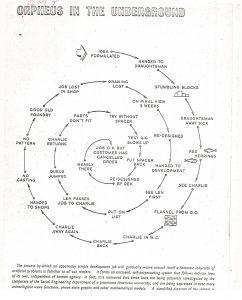

I grabbed what I thought was a reasonable selection of documents, photos, drawings, microfilms and catalogues and have used quite a number of them to help re-construct the OMT story. Looking through them again the other day, the following chart came to light and it shows that behind all that precision and professionalism, lurked a sense of humour hiding potential frustration at things that might get in the way of a smooth production flow. Click on the image and prepare to chuckle.

_Back to top_ _Next page_ _OMT References page_