Standard Products:

Here is a photo of an OMT Optical Flat in its case. The photo was sent to us in February 2020 by Nick Jung – a self-confessed “collector of junk”, having climbed into a skip to rescue it when a college was throwing out loads of stuff! He tells us the item is 7/16″ thick.

The two photos below are of a set of ex-ministry components produced in the High Wycombe factory. Reference to the Optical Elements catalogue indicates that these are Fused Quartz Micrometer Gauges. “These superior quality gauges, manufactured from fused quartz because of its hard wearing qualities and thermal stability, are designed specifically for checking the flatness and parallelism of micrometer measuring faces. They are supplied in sets of five, each calibrated to the fifth place and with the size engraved on the periphery.”

Thanks to Dave Caroline for sending these photos.

In March 2022 we received an email from Mark Wickers who unearthed a collection of OMT objects while clearing effects from a house in Windsor.

They were all in OMT cases, so he googled OMT to see what they might be, discovered our website and got in touch. Mark kindly supplied these photos, which show he has a selection of optical flats, micrometer gauges and several types of prism. The cases all date from the OMT Slough era, so they must have been manufactured between 1940 and 1953.

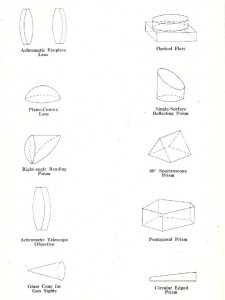

- Straight edges

- Parallel plates

- Reflective mirrors

- Lenses

- Achromatic eyepieces

- Plano-convex lenses

- Achromatic telescope objectives

- Meniscus lenses

- Prisms

- Right-angle reading prisms

- Single-surface reflecting prisms

- 60-degree spectroscope prisms

- 90-degree prisms

- Pentagonal prisms

- Circular-edged prisms

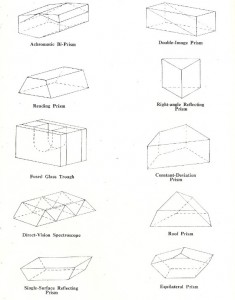

- Achromatic bi-prisms

- Reading prisms

- Double-image prisms

- Simple bi-prisms

- Combination prisms

- Graticule prisms

- Right-angle reflecting prisms

- Constant deviation prisms

- Roof prisms

- Bi-roof prisms

- Equilateral prisms

- Single-surface reflecting prisms

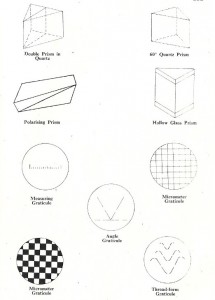

- Double prisms in quartz

- 60-degree quartz prisms

- Polarising prisms

- Hollow glass prisms

- Graticules

- Measuring graticules

- Micrometer graticules (both grid and chequer-board)

- Angle graticules

- Thread-form graticules

- Photo graticules

- Special Optics

- Direct-vision spectroscopes

- Fused glass troughs

- Glass cones for gun sights

- Optics Sample Set: A selection of some of the above items all in a velvet-lined presentation case, embossed with the name of Under-Water Cutters Ltd, Ormonde House, 26/27 St. James’s Street, London, SW1, as selling agents for OMT. The property at this address later appeared to have become a hotel: it is not known what became of Under-Water Cutters Ltd.

Here are some of the optics owned by Stan Gibbs, and the set he kindly put together as a gift for the author:

- Vertical Omtimeter: A high precision optical comparator, typically for the standards room. Capable of measurement to 0.00001″

Dave Caroline sent us the following pictures of a vertical omtimeter that he rescued some years earlier from the old Lanchester (later Jaguar) factory that was about to be demolished. It differs somewhat from the unit depicted above but it was clearly manufactured during the Slough era (up to 1953) and includes a wonderful wooden-housed transformer for powering the lamp. A sticker on the base of the Omtimeter shows that it has been calibrated by Hill & Cox Services, a company set up by two former employees.

In this photo, the unit is being used to check a gauge block against an OMT glass 1.0000″ block. You can find more of Dave’s photos at https://www.collection.archivist.info/searchv13.php?searchstr=omtimeter.

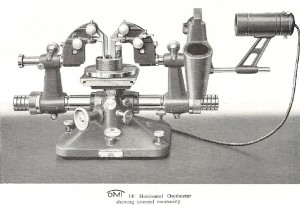

- Horizontal Omtimeter: A high precision optical comparator typically for inspecting plain or threaded holes.

Bill Head got in touch with us in September 2018 when his friend, Paul Leat, was closing his engineering business, to tell us about an old Horizontal Omtimeter (with one slightly bent probe) which he found buried and forgotten at the back of a shelf. Paul couldn’t remember where it had come from, but one of the photos he provided shows a “Brunel Metrology” sticker on the base.

A little research shows that Brunel Metrology Services Limited was a calibration house based near Midsomer Norton in Somerset, but has now become part of Rhopoint Metrology Limited of Birmingham. This seems to show that the previous owner (whoever that might have been) took care to keep the instrument calibrated. The manufacturer’s plate shows that the instrument was produced in the Slough factory, so that dates it as pre-1953.

We understand that Paul quite fancied keeping it as a piece of industrial art, but his wife thought the lounge was not an appropriate place for it. Bill thought perhaps he could provide a home for it but divorce proceedings were threatened when he suggested displaying it on his wife’s very expensive Yamaha piano! For a while, it looked as if it might end up as a piece of exquisite scrap metal. but in January 2019 Bill got in touch again to tell us the good news that it is now in the hands of T.S. Motors in Frome, where it is displayed on a custom plinth in their office. Tom, the owner of the business, is a fan of all elderly engineering items and seems pleased to have rescued it from the looming scrapheap. Many thanks to Bill and Paul for allowing us to post some of the lovely photos they provided of this old instrument.

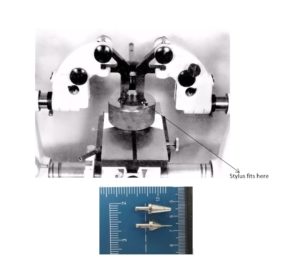

Bob Peacock sent us this photo of the internal measuring head for a Horizontal Omtimeter (click the image to enlarge). It shows the head being used to measure an internal thread. Two example styli are shown, although for thread forms the stylus would be ball-ended. Bob explained that each thread form would have a pair of styli for a range of sizes, the size being established with a table of values or against a master gauge.

- Optical Dividing Head: Two models were listed in the 1963 catalogue. Type OW7 incorporated a scale observed through a fixed eyepiece and reading directly to one minute of arc. Where a greater degree of accuracy was required, the type OW12 included a scale and micrometer eyepiece, allowing direct reading to two seconds of arc.

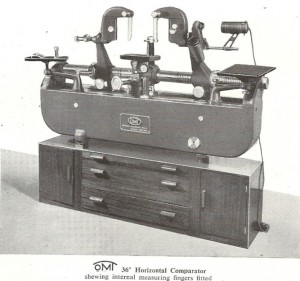

- Horizontal Comparator: A further development of the Horizontal Omtimeter, but for checking larger workpieces. Facilitates the checking of internal and external threads and tapers as well as internal and external cylindrical surfaces.

- Thread Form Inspection Machine: This simple machine met the demand for a simple, inexpensive means of checking a variety of threads by comparison with a master thread form.

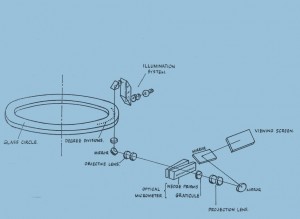

- Manual/Optical rotary tables of various diameters. The Slough factory produced 10″ and 16″ optical rotary tables (manual tables with optical position setting). The diagram below shows how the system of optics allowed the position of the table to be monitored without making any physical contact with the moving parts.

- Manual rotary-inclinable tables, embodying a rotary table that can be tilted up to 90

degrees were introduced in 1955. Most of the range could be offered with digital readout systems (as opposed to conventional optical setting) for ease of setting. During the 1970’s these were usually from the Digipac range manufactured by Newall Electronics, and incorporating OMT rotary gratings as the measuring device. The photos show an older small table, compared with a more modern, larger and very substantial-looking design, apparently destined for the Italian market.

degrees were introduced in 1955. Most of the range could be offered with digital readout systems (as opposed to conventional optical setting) for ease of setting. During the 1970’s these were usually from the Digipac range manufactured by Newall Electronics, and incorporating OMT rotary gratings as the measuring device. The photos show an older small table, compared with a more modern, larger and very substantial-looking design, apparently destined for the Italian market.The photos labelled FIG-1 and FIG-2 have clearly been labelled up ready for inclusion in the service manual. Click on the images for a clearer view.

- Automatic rotary tables were manufactured in various diameters up to 42” (1060mm). The first experimental table (c.1960?) used a prototype automatic positioning system made by Ekco (EK Cole & Company) and used Meccano components, including gears, which proved surprisingly accurate. Later, EMI became the favoured supplier of control systems employing punched paper tape input.

- During the 1970’s a customised control system was developed by Newall Electronics and provided shortest-path positioning with punched paper tape and manual data input in multiple angular formats (degrees-minutes-seconds, decimal degrees, decimal parts of a circle). The drive system used a dc servo-motor driving the worm-and-wheel mechanism of the manual tables and the angular position feedback transducer was an OMT rotary diffraction grating. Several of these control systems on 36” tables found their way into the workshops of Rolls-Royce (Filton) and KLM Airlines (Schipol airport). One at Filton was used in conjunction with a special punch and die set to stamp an accurate pattern of diagonal slots in a ring manufactured from thin stainless steel. It formed the basis of a transducer that was fitted around the periphery of the compressor blades in pre-production versions of the Pegasus engine fitted to the Harrier vertical take-off fighter aircraft, to enable engineers to study vibration of the blade tips under various operating conditions. Other control systems included those from Slo-Syn (using stepper-motors) as shown in this photograph of a dual-table setup being tested by Ray Slade.

- By the time OMT ceased operations they could offer rotary tables from 8” (203mm) diameter, all the way up to a 72” (1829mm) model weighing over 4 tonnes. [[Can anyone identify the gentleman in the photo?]]

The following photo, taken at the 1961 Machine Tool Exhibition in Brussels, shows Joe Hobbs demonstrating a 30″ rotary table to Lord Hailsham, then Minister of Science.

- Several interesting articles were published in Machinery in 1965, focussing particularly on the OMT rotary table product range and manufacturing techniques. They were later released as a booklet entitled “Building Precision Into OMT Optical Rotary Tables”, which we have been able to make available (as a 5MB download) here with the kind permission of Machinery, published by Findlay Media, a Mark Allen Group company – https://www.machinery.co.uk

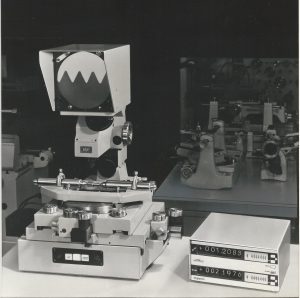

- Toolmakers’ Microscope: For accurate inspection of thread forms, form tools and complex contours. Observation through an ocular or by projection onto an integral screen.

It is nice to be able to include a photograph (above) of one of these instruments (using an ocular) that is still in regular use (2016) by the final owners of OMT, Rotary Precision Instruments UK Ltd.

The second photo shows a later development of the range, the model BL50. This used linear diffraction gratings and a DRO (Digital Read-Out) display unit instead of the original micrometer heads. The diffraction gratings were manufactured by OMT and the digital readout system is from the Newall Electronics ‘Digipac’ family. The unit in the photo is fitted with a projection head, which was more convenient for the operator than using the eyepiece.

- Lathe Tool Setting Microscope: Designed for use on a lathe or similar machine to enable the operator to set the screw cutting tool in the correct position accurately and quickly, relative to the work, and also to check the thread angle.

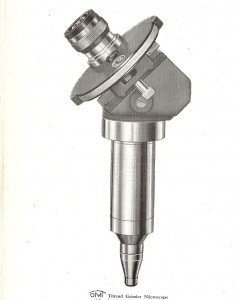

- Thread Grinder Microscope: Designed for use on thread grinding machines for checking the form and position of the thread during the grinding operation.

- Roundness Measuring Machine: Developed in conjunction with the National Engineering Laboratory, East Kilbride, this machine employed air bearing technology to measure roundness to a high degree of accuracy on parts having diameters of up to 6” (152mm).

- Projection Pantometers: A range of instruments used particularly for inspection of 3-dimensional contours, such as turbine blades. A variation on this theme could be found in the Napier-OMT contour and profile projector, which introduced novel features to assist in the inspection of aircraft engine compressor and turbine blades.

- Universal Projector: A universal projector with a 15” (380mm) diameter rotary projection screen was available in the 1960’s. It had been developed for determining the accuracy of contours such as templates, gears, cam forms, screw threads, etc.

_Back to top_ _Back a page_ _Next page_ _OMT References page_