[[Copies of a Government report believed to be dated from 1944 is available from The National Archives. Included with the report are plans of the Fletton High Street (No.1) factory layout. It is interesting to see that the grounds included 10 air raid shelters, (2 at the north end of the site – near the road, and 8 at the southern end of the site) which were used by the company’s employees when the air raid sirens were sounded. We have no knowledge of these ever being used, other than for air raid drills. The same plan shows the site of the ‘Fletton Council School’, also at the northern end of the site. Included in the school grounds were two air raid shelters. The local air raid siren was mounted on the vegetable processing factory (Farrows) over the road and on the other side of the railway]]

[[The following information has been compiled from this survey report.]]

Introduction.

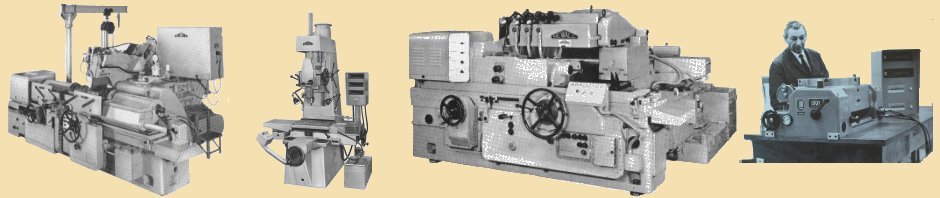

Newall Engineering “was chosen for the machine tool survey because they are the only firm in Great Britain manufacturing Jig Boring machines, probably the most important machine tool in the Tool making department of any factory complex. It is designed primarily for boring holes in jigs to a tolerance better than one tenth of a thousandth part of an inch, thus it is probably one of the most accurate type of machine tool made.”

“The firm also manufacture plain grinders; thread grinders and lapping machines; and are also well known as manufacturers of a large quantity of all types of gauges and gauging equipment.”

Description of works.

The survey describes the factory at Old Fletton in detail, including details of the factory buildings (“about 118,250 sq. ft. of which the built up area is about 69,600 sq. ft. with floor area of 74,900 sq. ft.“). The survey goes on to note that while the company manufactures machines (jig borers, grinders etc) to a very “high degree of accuracy“, this is achieved by the methods and skills employed despite using standard (“not specifically built, or modified“) production machines. “The value of the buildings is given as £48,400.”

Production plant.

The plant equipment is described as “of a being normal type found in a light to medium engineering works: there are some important large machines used for first operations in planing and boring the large castings, and used in constructing the jig borers and other machines fabricated by this firm. Other plant is used in fabricating the sub assemblies and components.”

“Replacement of plant appears to be the same as for other firms dealt with in this survey, i.e. up to 3 months for small machines and up to 12 months for the large planers and borers.” [[We suspect that those replacement figures were mis-quoted, and should be YEARS, not MONTHS.]]

“The value of plant is given as £92,961 for their own plant, and an additional £109,000 for plant belonging to the government. In addition, jigs and patterns are valued at £16,893.”

Personnel.

“There is a total staff of about 832, divided into operatives 537; non productive workers (such as charge hands; labourers; stores and progress; inspection) 195; office staff approximately 100. There are two shifts: 8 a.m. to 7.30 p.m. on day shift; 8 p.m. to 7.30 a.m. on night shift.

“About 75% of the personnel work on day shift and the remaining 25% on night shift.”

Output.

[[These calculations do not add up! Note also that a later section in the Survey report, covering ‘statistical information’ does not match the figures given in this ‘Output’ section!]]

“The output of Jig Borers is made up as follows:-

No.0: 30 machines valued at £1,020 each

No.1: 46 machines valued at £1,419 each

No.2: 2 machines valued at £2,975 each”

“Equipment for these is valued at £12,673 in addition; making the total value of 98 machines and equipment of £144,150.”

“Output of Plain Grinders is as follows:-

Size 10×24: 17 machines valued at £807.10.0 each

Size 10×36: 163 machines valued at £892.10.0 each

Size 10×48: 63 machines valued at £977.10.0 each”

“Equipment for these is valued at £19,214 in addition; making the total value of 243 machines and equipment of £240,469.”

“Output of Thread grinders is as follows:-

21 machines (18 – No.420; 3 – No.836) with equipment £48,845

“Output of Lapping machines is valued at £28,848

“Output of Gauges is valued at £141,688

“Output of Sundries is valued at £3,384

“Omtimeters are valued at £11,588, but since these are constructed at the firm’s Slough factory, it has not been included in the grand total of £807,384.” [[Using the reports own figures, the grand total should be £607,384!]]

Machine Manufacturing Time Cycle.

The survey report provides the following information of each machine type (per machine):

| Machine | Type | Machining Hrs | Fitting Hrs | Electrician Hrs | Painter Hrs | Total Hrs |

| Jig Borers | No. 0 | 910 | 555 | 75 | 60 | 1600 |

| No. 1 | 990 | 840 | 75 | 80 | 1985 | |

| No. 2 | 1980 | 1680 | 150 | 160 | 3970 | |

| Plain Grinders | 860 | 570 | 75 | 75 | 1580 | |

| Thread Grinders | No. 420 | 1900 | 2020 | 90 | 70 | 4080 |

| No. 836 | 2325 | 2525 | 112 | 87 | 5049 | |

| Lapping Machines | 710 | 590 | 35 | 60 | 1395 | |

Production Loss Risk.

In this section of the survey report, the report authors attempt to determine the potential causes for loss of production, and the resulting time delay before production can resume.

“The firm consider that the areas of the machine shop containing the large planers and borers has the largest potential loss of production due to the length of time necessary for building of similar machines, in the case of damage or destruction. A shorter term risk is that attached to the finished parts stores. If these stores were destroyed, it is possible that production of finished machines would be set back up to 3 months, until new sub-assemblies and components could be fabricated.”

Statistical Information.

[[The final section in the reports is a summary of many of the figures already contained in the report, but there are a number of differences between these figures, and those given earlier. For example, the value of jig borer production gives a total of £114,000, but is then quoted as £144,000. Calculating the total for all machine types together produces an overall output figure of approx £607,384. However, in the ‘Statistical Information’ chart, a figure of £807,384 is given. Are these just typing errors?]]

Other information in this section specifies that:

“Total number of machine produced each year: approx 400”

“Factory power requirements:”

“Electricity, per month (supplied by the Town’s Electricity undertaking): 730,000 Kw.” [[We suspect that this should be 730,000 KwH over the month, which equates to a steady load during production periods of approx 1200 Kw. This assumes 2 shifts of 10 hours for 28 days in the month (this was war time, and these working hours were not uncommon).]]

“Gas, per month (supplied by the local gas company): 500,000 cu. ft.”

Back to top.