This web page was last updated in November 2022.

The history of the Newall company prior to its move to Peterborough is covered on our ‘Brief History‘ page, and a news article in the Peterborough Standard newspaper dated 22nd February 1935 (this article is transcribed on our ‘Old News‘ page).

At that time, the company had a reputation for its large range of precision gauges, high accuracy measuring machines, and special precision instruments. The company was also manufacturing the Norton Lapping machines.

We continue the story below, using information from documents held by ‘The National Archives’ service, the company’s ‘Report and Accounts’, various other sources, and memories provided by ex-employees. If you have information or memories that we could add to the Newall story, or if you are aware of any errors on our webpages, then please contact mike@newall.org.uk, or use the feedback form on our feedback page.

Note. This ‘Newall Engineering Company‘ page gives details of that company, AND the ‘Newall Machine Tool Company‘ which, in 1964, became the holding company for Newall Engineering and its subsidiary companies (known as The Newall Group of Companies). Where we refer to sales, turnover and profit figures, these relate to the holding company, not the individual companies within the group.

At the time of the move to Peterborough, Newall Engineering was being managed by two individuals who were instrumental in the significant growth of the organisation over the following years. These were Mr Sydney Player (the proprietor) and Mr Kenneth Summers (General Manager). Both men had previously worked for a number of years in America where they gained significant experience of the machine tool business. Mr Summers had returned to the UK in 1928 to manage the Newall company for Mr Player. When Mr Player returned in 1933, intensive development of the machine tool side of the business commenced.

As indicated in the 1935 newspaper report, the Old Fletton site had been owned and operated by Atkins (Peterborough) Ltd. When the Newall company acquired the site at the end of March 1935, it added the Atkins company’s thread grinder products to its production range, and took on a number of its work force. Mr Sydney Player had stated that he expected the thread grinder products would become a significant part of Newall’s production. (We believe the Fletton site’s previous owner, Mr Harry F Atkins, also joined the company, though we have not been able to confirm this. A book entitled ‘Screw threads, some ideas on standardisation’ by Harry F. Atkins was published in 1944.)

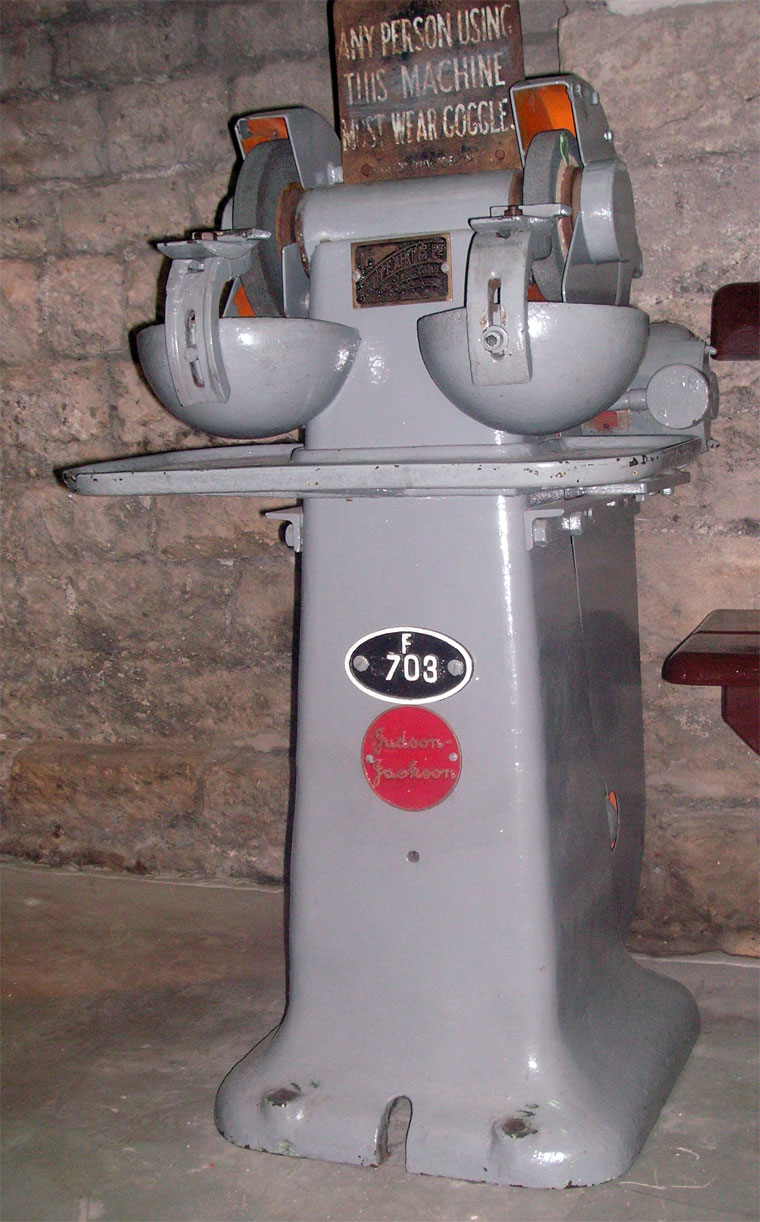

The following photo shows that company’s plant-number plate on a Judson-Jackson pedestal tool grinder. It is now installed at the Swindon Steam Museum but the plate indicates that it had previously been owned by the Harry F Atkins company.

It was spotted by a former local lad, Geoff Sutton, during a visit to the museum in October 2018. It caught his eye because he went to the grammar school in Old Fletton back in the 1950’s and wondered if it might have anything to do with Newall’s history, as he couldn’t remember any other engineering companies in Old Fletton. How right he was! Thank you for sending this in, Geoff.

In 1936, the company raised additional capital to fund further expansion of its manufacturing facilities, and product range. A prospectus relating to that share issue provides some interesting information about the company’s products and customers – see here.

In 1937, Sydney Player’s son, Denis, joined the board.

1940 saw the formation of a new company – Optical Measuring Tools. This company was wholly owned by Newall Engineering, and was its first subsidiary company. Go to our OMT pages for more information on this company.

Both Sydney Player, and Kenneth Summers were founding members of another subsidiary company (‘Keighley Grinders‘) which was inaugurated in 1942. This new company acquired the business of ‘Quality Machine Tools’ of Aireworth Road in Keighley from its Official Receiver, and continued to operate from the Aireworth Road site. Visit our Keighley Grinders page for more information on this company.

In 1944, the Ministry of Home Security undertook a survey of certain principal engineering companies, and Newall Engineering was chosen because “they are the only firm in Great Britain manufacturing Jig Boring machines, probably the most important machine tool in the Tool making department of any factory complex”. Copies of the survey report are available from The National Archives, and a summary of the information can be seen here.

The survey report includes plans of the Fletton High Street (No.1) factory layout. It is interesting to see that the grounds included 10 air raid shelters, (2 at the north end of the site – near the road, and 8 at the southern end of the site) which were used by the company’s employees when the air raid sirens were sounded. We have no knowledge of these ever being used, other than for air raid drills. The same plan shows the site of the ‘Fletton Council School’, also at the northern end of the site. Included in the school grounds were two air raid shelters. We understand that the local air raid siren was mounted on the vegetable processing factory (Farrows) over the road and on the other side of the railway.

The ‘raw’ castings were an essential part of any machine tool, and in order to produce a quality machine to meet the required strength and stability characteristics, these casting must be manufactured to exacting standards. The casting (base, table, column, workhead etc) were designed by Newall, and patterns were manufactured at the Fletton factory. We believe that the castings themselves were manufactured by ‘James C Kay’, a firm based in Bury, using the patterns supplied by Newall.

‘James C Kay & Co.’ was inaugurated in 1905, but had been managed by an Official Receiver since 1935. In 1946, Newall appeared to have gained a controlling interest in the firm, and had made their own appointments to the company’s board of directors. In 1959, the company changed its name from ‘James C Kay & Co.’ to ‘Newall Precision Foundries’.

Castings were stored for a number of months in the open at the Fletton factory, where they were exposed to the weather. We understand that this was done to “season” them, in much the same way as wood is stacked to season it. We’ve been told that the heating and cooling treatment performed some kind of stress-relieving action.

In 1947 a new company, ‘Newall Sentinel’ was inaugurated. A year later, its name was changed to ‘Newall Group Sales’. [[We have not yet researched the information on this company.]]

Sydney Player’s second son, James Calvin Player (Jim), was elected to the board of directors in June 1948. Jim was already a director of Optical Measuring Tools.

A new factory at Shrewsbury Avenue [[off Oundle Road]] opened in 1957, which more than doubled the manufacturing capacity of the company. This factory became known as the No.2 factory.

1964 saw an administrative reorganisation of the group with the incorporation of a new company called Newall Machine Tools Company Ltd. This new company became the holding company for all the companies in the group – namely:

- Newall Engineering Company Ltd

- Optical Measuring Tools Ltd.

- Newall Precision Foundries Ltd.

- Keighley Grinders (Machine Tools) Ltd.

- Newall Group Sales Ltd.

- The Newall Machine Tool Corporation of Canada Ltd.

- Stockdale-Newall Machine Tools (Proprietary) Ltd.

<<In April 2020, information from Andrew Davies gave a bit more information about Stockdale-Newall Machine Tools (Proprietary) Ltd. Andrew’s post also refers to two brothers that he thought were called Frank and Eric Player who setup a company in Australia called ‘Player Bothers Proprietary Ltd.’ in 1960 and used Newall jig borers. Further research suggests that Frank was Sydney Player’s brother, and that between them, they registered the Australian company ‘Player Brothers Pty Ltd. Read more about this on our Feedback page. >>

Newall Engineering Company (now a subsidiary company of Newall Machine Tools) retained the Peterborough based machine tool business, together with its premises at Fletton High Street, Old Fletton; land at Shrewsbury Avenue, Woodston; and land and premises being part of “Steadmans Field” at Padholme Road.

In the mid-1960’s, Newall Engineering and Matchless Machines Limited (MML) undertook a joint development to provide a ‘spark erosion’ machining process for the Newall range of jig borers. Details can be found on our Products pages here.

1968 saw the company announce that an agreement had been signed with Houdaille Industries Inc (USA) for Newall to manufacture and market the range of Burgmaster machines “for all outlets in Europe and certain other territories. We have felt for some time that it would be advantageous to expand our activities in the jig-boring field to enable us to cover the full range of equipment for making holes, and we are hopeful that when the benefits of our association with Houdaille Industries Inc. are realised we will be able to offer a wider range of products in this field.”

This agreement led to the birth of Newall Burgmaster Limited (incorporated on 30 May 1968), which operated from a factory in Croydon. Unfortunately, this venture was short lived, and the factory closed in mid-1971 with all the employees at that factory being made redundant.

The Newall Group continued to increase its turnover through to the early 1970’s with sales reaching £4m. From 1971, turnover declined, profits became losses, and the company reported a difficult trading environment, particularly in the UK. This resulted in a significant cut back of production capacity, with staff redundancies and the closure of the No1 factory (Fletton High Street) and the OMT factory in Helston in 1973. For the two years ending March 1972 and 1973, the company reported a loss just short of £600,000 and just over £700,000 respectively.

In May 1973, both Denis Player and James Player resigned from the board of directors. At the company’s Annual General Meeting in November 1973, a special resolution was passed making Denis Player ‘Honorary President’ of the company.

A  graph showing the order intake for the Newall Group covering 13 consecutive financial periods during 1973 and 1974 was published with the Newall Machine Tools’ Report & Accounts for the year ending March 1974. This demonstrated the volatile nature of the business’ order intake – for example, the Newall Engineering sales for each period varied between about £150,000 and £250,000. In period 5, an order from Ford of Africa provided a boost to almost £600,000, and in period 13, an order from Ford of Spain boosted the sales figures to just over £900,000. (Click on the graph to enlarge the image.)

graph showing the order intake for the Newall Group covering 13 consecutive financial periods during 1973 and 1974 was published with the Newall Machine Tools’ Report & Accounts for the year ending March 1974. This demonstrated the volatile nature of the business’ order intake – for example, the Newall Engineering sales for each period varied between about £150,000 and £250,000. In period 5, an order from Ford of Africa provided a boost to almost £600,000, and in period 13, an order from Ford of Spain boosted the sales figures to just over £900,000. (Click on the graph to enlarge the image.)

The annual report for the year ending March 1974 showed a reduction in the loss figure to £288,000 and expressed some optimism about future prospects. The report also stated “that the three-day week caused little disturbance to the Group’s activities due to special measures taken, and as a result “of magnificent efforts by staff and shop-floor personnel“.

The same annual report recorded that the company had been notified that The Minden Investment Trust Ltd. had acquired 11.8% of the ordinary shares in the holding company (Newall Machine Tool Co. Ltd.). Perhaps this was an early indication of a possible take over bid ?

The Report & Accounts for year ending March 1976 highlights the following issues:

- A 5 year phased repayment of a loan of £250,000 from the Department of Industry in relation to the factory at Helston has been agreed. Interest will be paid at a rate of 7.5% on the outstanding balance during that period.

- “A shortage of orders led to a reduction in personnel at M. T.Hydraulics Ltd., which traded at a loss, and at Tooling and Spares division at Fakenham, whose profits were drastically reduced.“

- “Whilst RiNewall Espanola S. A., which was established last year, has continued to make progress, our merchant company in Spain, O.F.I.E.S.A., suffered severely from continued difficult trading conditions, and recorded a substantial loss. Therefore, the decision has been made to curtail drastically the activities of O.F.I.E.S.A.”

- “The planned programme of increasing the company’s product range has continued with an agreement with Glevum Ltd. of Gloucester for the joint development, manufacture and sale of a range of electric discharge (spark erosion) machines.”

- New products shown at the Mach ’76 Exhibition in Birmingham include the ‘Vertex’ NC vertical milling centre from Newall Engineering; ‘Spherosyn’ from the Electronics Division; and a new range of machines from the Keighley Grinding Company.

- “M. T. Hydraulics have developed a specially high-quality range of hydraulic valves called ‘MaTcHless’ valves, containing important patented improvements.”

The financial years ending March 1975, 76 and 77 saw a marked improvement in turnover (1977 output £7,776,000) and a return to profit (1977 profit £1,258,000).

1977 was the year in which the Newall group was taken over by B. Elliott.

1978/79 saw a significant expansion of the production capacity at the No.2 factory in Peterborough with the construction of a fifth bay to the factory. This was used for the manufacture of a range of roll grinders following the acquisition in 1980 of the Churchill grinding business from Alfred Herbert Ltd. Turnover during this period increase to over £10,000,000, with profits exceeding £1,200,000.

Turnover increase further in 1980/81 (reaching £14,450,000), but profits declined significantly.

In January 1983, as reported in the Peterborough Evening Telegraph, redundancies reduced the workforce at the Peterborough sites by half.

The year ending March 1983 saw turnover declining and profits becoming losses once again – a loss of £1,116,000 was reported on a turnover of £10,544,000. Over the same period, the number of employees (for the Newall Group as whole) dropped from 874 to 527.

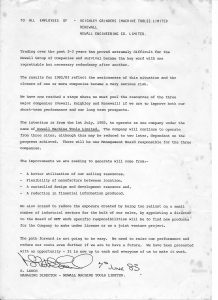

The image of the left is a copy of a letter issued in June 1983 by the then Managing Director, Keith Leech. The (rather depressing) document makes clear that the company is struggling for survival.

The decline in orders, and profitability meant that just a few years after the expansion of the No.2 factory in Peterborough, it closed in 1985. To complete the design and manufacturing drawings for outstanding orders for the Newall Engineering range of grinders (primarily CNC cam shaft grinders destined for America), the design/drawing office was moved, initially into the apprentice school on the same site, and then to a unit in Manasty Road, Orton Southgate, Peterborough. Production of these machines was moved to the company’s Keighley works.

Three newsletters produced by Butler Newall in 1985, 86 and 87, provide an interesting insight into the company’s problems. These documents were:

- Kephax – Autumn 1985. This includes a short article on page 2 headed ‘Peterborough Move’ which is about the move from the apprentice school in Shrewsbury Avenue to Manasty Road, Peterborough.

- Kephax – Spring 1986. Also on page 2, an article headed ‘An Alternative A-Z of Peterborough’. Written by Dawn Winter, this article loosely describes the layout of the Manasty Road site.

- Kephax – Spring 1987. Although a year before the Manasty Road site closed, there is no mention of the company’s Peterborough operations.

The Manasty Road site closed at the end of March, 1988. This brought to an end Newall’s engineering business in Peterborough. The electronics company continued to operate from their Ivatt Way premises for a few more years – see Newall Electronics.

Please refer to our KEIGHLEY GRINDERS and ADDENDUM page for more information relating to the Newall business after this closure.

FACTORIES – This page gives more detail of the Fletton High Street factory (N0.1), the Shrewsbury Avenue factory (No.2) and the Padholme Road factory (No.3).

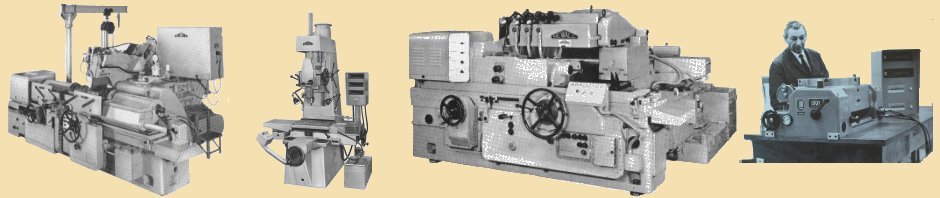

PRODUCTS – For details of the machines manufactured by the Newall Engineering Company, visit our ‘products‘ pages.